AQP provides design, development and manufacturing, including testing and diagnostics of the manufactured equipment at our hydraulic testing facility. The entire development and manufacturing process is certified according to QMS standard ISO 9001: 2015 LRQA (Lloyd's Register Quality Assurance).

Depending on the complexity of the solution (especially when developing prototypes and single-purpose machines), we provide during the 3D modeling phase and assembly phase analysis and optimization of previous designs and original projects to prevent construction defects before production begins.

The key of our competitive advantage is our KNOW-HOW and many years of experience on the field of manufacturing technology and material properties during machining, AQ PUMPY is searched by engineering companies and designers for consulting, helping and re-designing. Before the start of production we are able to detect difficulties of manufacturing and assembling individual parts, whether the final product will work, which parts of the machine will be most stressed and where can be higher wear of the parts expected. At the same time, we draw attention to the user's drawbacks, which is quite clear for us at this stage of the developing.

After careful consideration, we are proposing the design that simplifies the final device and especially makes the production and installation cheaper. Furthermore, we are re-designing the engineering project to make the prototype device primarily functional, and to make the most stressed parts as cheap as possible, and easily change even by end-users to reduce the maintenance costs. Of course, there is always a constant effort to adjust the device to comfortable use by the end customer, in addition to the maximum simplification of machine application itself and ease of washability, storage, etc.

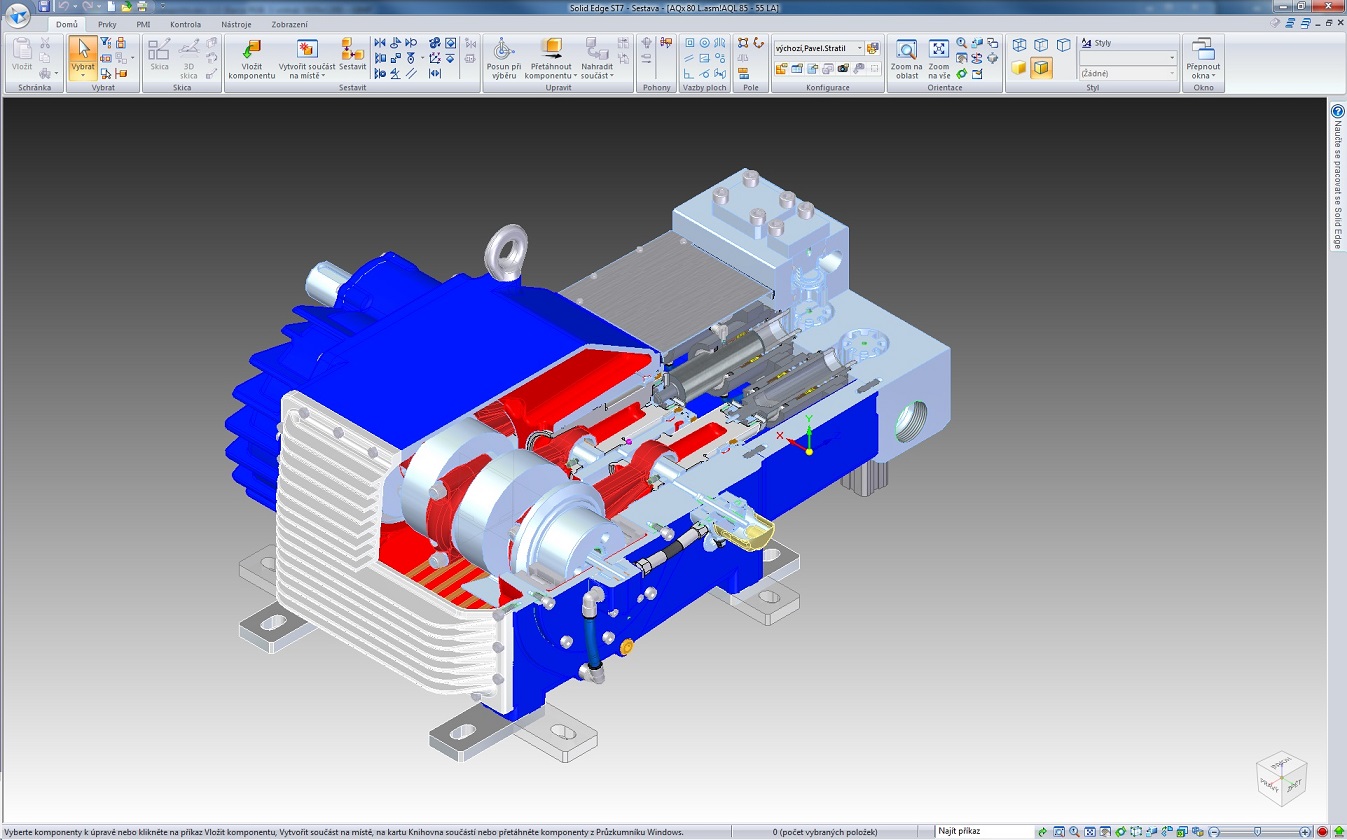

Our developers and designers are able to flexibly customize individual design processes to meet customer needs when creating new parts, components, tools or entire machines. We usually start with assembly, continuously we create 3D models, until the entire design is completed. Then we make drawings from these 3D models and assembly for manufacturing and controling purposes. According to the complexity of the design we provide optimization of the preliminary drafts/projects during the stage of creating 3D models and assembly.

For the purposes of development and construction, we use the Siemens program: Solid Edge ST7, including modules:

Contact for more information:

Phone: +420 581 604 912

mob .: +420 606 741 282

Email: aqp@aqpumpy.cz

Email: langer @ aqpumpy.cz